Alaabta

Dhuxul gacmaha Tungsten Carbide sibidhka ee Goobta Saliidda Submersibe

Hordhac Product

Codsiyada gacan-gacmeedka Tungsten carbide waa ballaadhan yahay, taas oo ah qalab lagu ilaaliyo fasalka qaybaha.Waxay ku jirtaa shaqada dhabta ah iyo doorka iyo ujeedada deegaanka codsigeeda waxay leeyihiin xiriir weyn.

Codsiyada Valve-ka, bushings ayaa lagu rakibaa dabinka daboolka taamka, si loo yareeyo daadinta waalka, si loo xidho;codsiyada xajinta, isticmaalka baadiyaha si loo yareeyo xirashada inta u dhaxaysa xajinta iyo kursiga, iska ilaali farqiga u dhexeeya shafka iyo daloolku korodho iyo wixii la mid ah.

Tungsten carbide gacmo-soo-saarka iyo farsamaynta xoogga sare, waxay u adkeysan kartaa culeys dheeraad ah, oo leh xasillooni kiimiko oo sarreeya, alkali, khamriga, ether, hydrocarbons, acid, saliid, saabuunta, biyaha (biyaha badda), oo aan lahayn ur, aan sun ahayn, dhadhan la'aan, sifooyinka aan miridhku ahayn, ay si weyn loogu isticmaalo warshadaha petrochemical ee bamka saliidda quusin, bamka slurry, bamka biyaha, Bamka Centrifugal, iwm.

faa'iidooyinka

1, 100% walxo ceeriin:

Bushings waxaa lagu soo saaraa alaab cayriin oo saafi ah, taas oo leh sifooyinka nolosha adeegga dheer iyo waxqabadka xasilloon.

2, Making:

Bushings waxaa lagu farsameeyaa qalabka saxda ah ee sare: Xarunta mashiinka CNC, mashiinka wax lagu shiidi karo, mashiinka wax lagu shiidayo, mishiinka qodista, mashiinka wax lagu shiidayo, mashiinka chamfering, Stamping Birta, mashiinka goynta CNC iwm.

3, Cabirro badan ayaa la heli karaa:

Waxaan ku siin karnaa bushings xajinaya cabbirro kala duwan, caaryada dhameystiran iyo waqti gaaban gaarsiinta.7-10 maalmood oo muunado .20-25 maalmood shaqo ee wax soo saarka ballaaran.

4, Xaqiijinta tayada:

Heerarka Tayada Aan La dhaafin

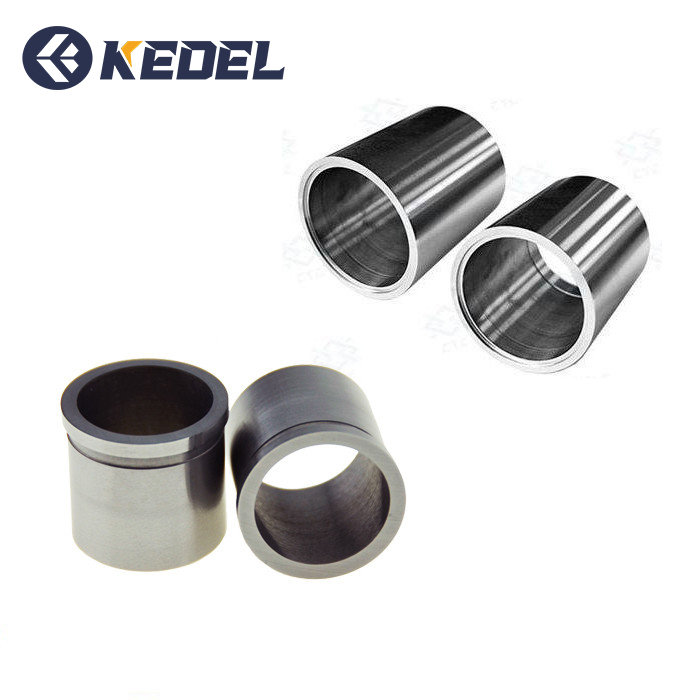

Bandhig

Sawir faahfaahsan

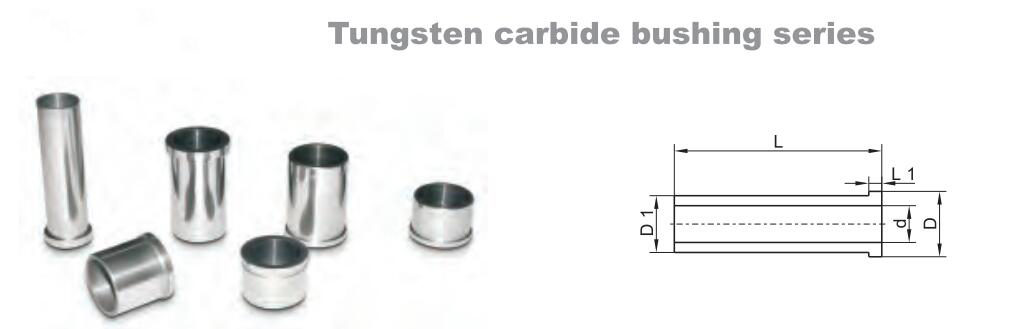

Miiska alaabta

| Darajo | ISO | Tilmaamid | Codsiga carbide tungsten | ||

| Cufnaanta | TRS | Adag | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | U qalma mashiinada kabka la qaboojiyey, birta shubka daawaha ah, birta celisa iyo birta daawahaSidoo kale u qalma mashiinada kabka caadiga ah. |

| YG06 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | U qalma farsamaynta dhamaystirka iyo farsamaynta badh-dhamaadka ee birta kabka ah, birta aan birta ahayn, daawaha iyo alaabta aan daawaynta lahayn.Sidoo kale u qalma sawirista siliga birta iyo birta aan birta ahayn, laydhka korantada ee isticmaalka juqraafi iyo birta iwm. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | U qalma farsamaynta qallafsan ee birta kabka ah, birta aan birta ahayn, alaabta aan birta ahayn, sawirista birta, birta aan birta ahayn iyo tuubooyinka, laylisyada kala duwan ee isticmaalka juqraafiyeed, qalabka wax soo saarka mishiinka iyo xidhashada qaybaha. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | U qalma farsamaynta xawaarihiisa hoose, daawaynta titanium-ka-shiidka iyo daawaynta refractory, gaar ahaan qalabka la gooyey iyo jeexjeexa xariirta. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | U qalma samaynta laylisyada laylisyada culus ee dhagaxa: jajabyada la goyn karo ee loo isticmaalo qodista godka qoto dheer, trolleyga dhagaxa dhagaxa iwm. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | U qalma qodista dhagaxa adag, biraha birta ah ee leh saamiga cadaadiska sare, sawirida tuubada, qalabka feerka, golaha xudunta u ah biraha birta ah ee tooska ah iwm. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | U qalma samaynta dhimasha saamaynta hoose leh sida qaybaha saacadaha feedh, qolofka baytariga, koofiyadaha yaryar iwm. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | U qalma samaynta caaryada madaxa qabow, shaabada qabow iyo riixista qabow ee loo isticmaalo soo saarista qaybaha caadiga ah, biraha iwm. | |

Miiska cabbirka

| Qaabka No. | Tilmaamid | OD(D:mm) | Aqoonsiga (D1:mm) | Pore(d:mm) | Dhererka(L:mm) | Dhererka tallaabada (L1:mm) |

| KD-2001 | 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| KD-2002 | 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| KD-2003 | 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| KD-2004 | 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| KD-2005 | 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| KD-2006 | 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| KD-2007 | 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| KD-2008 | 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| KD-2009 | 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| KD-2010 | 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |