Alaabta

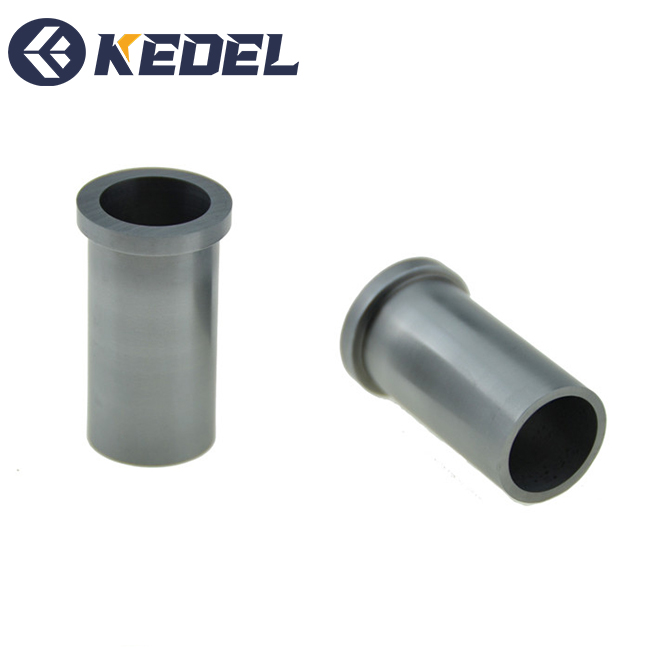

Kahortagga Daxalka Tungsten Carbide Adag YG1C Bushings Drill

Hordhac Product

Bushing Tungsten carbide lagu rakibay walxo carbide tungsten bikrad ah. Waxay muujinaysaa adkaansho sare iyo xoog foorarsi. Taasi waxay leedahay waxqabad heer sare ah oo ku saabsan iska caabinta xoqidda iyo daxalka, kaas oo si ballaaran looga isticmaalo warshado badan

Si ballaaran loo isticmaalo. Bushing Tungsten carbide waxaa inta badan lagu sameeyaa saxnaan sare, oo ay ugu wacan tahay dhammaystirkooda saxda ah, cabbirka saxda ah, adkeysiga iyo iska caabinta daxalka. Kuwaas waxaa aad ugu mahad naqay macaamiisha suuqa gudaha iyo kuwa saaranba.

Intaa waxaa dheer, ka duwan yahay jawiga codsiga kala duwan. Waxaa jira dhowr nooc oo kaynta carbide Tungsten ah. Inta badan qeexitaannada dhammaantood waa la habeeyey. Kedel Tool waxa taageeray aqoonta hodanka ah ee warshadaha iyo waayo-aragnimada wax soo saarka ee baadiyaha carbide ee Tungsten. Tani waxay soo saari kartaa noocyo kala duwan oo duurka Tungsten carbide ah oo ku salaysan naqshad gaar ah.

Tilmaamaha Alaabta

1. Isticmaal 100% tungsten carbide alaabta ceeriin

2. Qalabka kiimikaad ee deggan

3. Waxqabadka aad u fiican iyo iska caabbinta daxalka / daxalka wanaagsan

4. HIP sintering, compactness wanaagsan

5. Madhan, saxnaanta mashiinka sare ee saxda ah

6. OEM cabbirada la habeeyey waa la heli karaa

7. Bixinta Warshada

8. Hubinta tayada alaabta adag

Sawir faahfaahsan

Miiska alaabta

| Darajo | ISO | Tilmaamid | Codsiga carbide tungsten | ||

| Cufnaanta | TRS | Adag | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | U qalma mashiinada kabka la qaboojiyey, birta shubka daawaha ah, birta celisa iyo birta daawaha Sidoo kale u qalma mashiinada kabka caadiga ah. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | U qalma farsamaynta dhamaystirka iyo farsamaynta badh-dhamaadka ee birta kabka ah, birta aan birta ahayn, daawaha iyo alaabta aan daawaynta lahayn. Sidoo kale u qalma sawirista siliga birta iyo birta aan birta ahayn, laydhka korantada ee isticmaalka juqraafi iyo birta iwm. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | U qalma farsamaynta qallafsan ee birta kabka ah, birta aan birta ahayn, alaabta aan birta ahayn, sawirista birta, birta aan birta ahayn iyo tuubooyinka, laylisyada kala duwan ee isticmaalka juqraafiyeed, qalabka wax soo saarka mishiinka iyo xidhashada qaybaha. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | U qalma farsamaynta xawaarihiisa hoose, daawaynta titanium-ka-shiidka iyo daawaynta refractory, gaar ahaan qalabka la gooyey iyo jeexjeexa xariirta. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | U qalma samaynta laylisyada laylisyada culus ee dhagaxa: jajabyada la goyn karo ee loo isticmaalo qodista godka qoto dheer, trolleyga dhagaxa dhagaxa iwm. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | U qalma qodista dhagaxa adag, biraha birta ah ee leh saamiga cadaadiska sare, sawirida tuubada, qalabka feerka, golaha xudunta u ah biraha birta ah ee tooska ah iwm. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | U qalma samaynta dhimasha saamaynta hoose leh sida qaybaha saacadaha feedh, qolofka baytariga, koofiyadaha yaryar iwm. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | U qalma samaynta caaryada madaxa qabow, shaabada qabow iyo riixista qabow ee loo isticmaalo soo saarista qaybaha caadiga ah, biraha iwm. | |