Alaabta

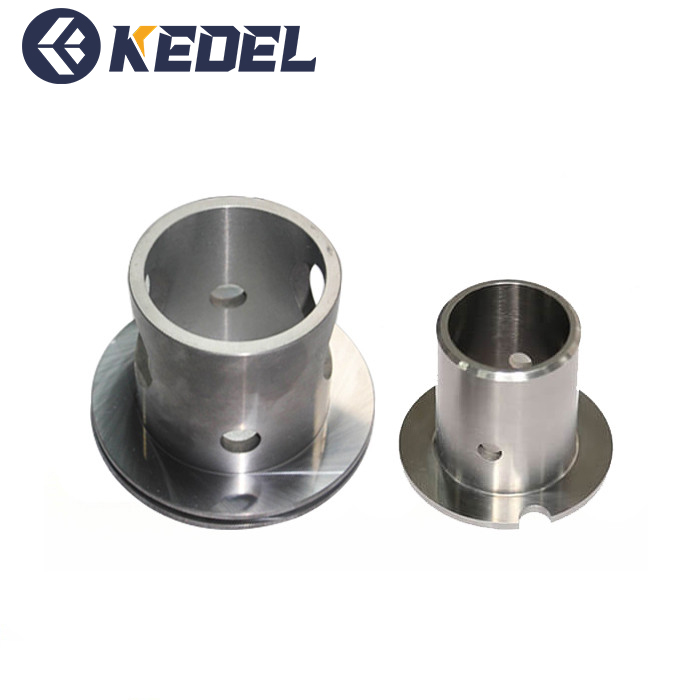

Tungsten carbide la habeeyay oo Bushing Shaft Sleeve

Hordhac Product

Codsiyada baadiyaha carbide Tungsten waa ballaaran, taas oo ah qalab lagu ilaaliyo fasalka qaybaha. Waxay ku jirtaa shaqada dhabta ah iyo doorka iyo ujeedada deegaanka codsigeeda waxay leeyihiin xiriir weyn. Codsiyada Valve-ka, bushings ayaa lagu rakibaa dabinka daboolka taamka, si loo yareeyo daadinta waalka, si loo xidho; codsiyada xajinta, isticmaalka baadiyaha si loo yareeyo xirashada inta u dhaxaysa xajinta iyo kursiga, iska ilaali farqiga u dhexeeya shafka iyo daloolku korodho iyo wixii la mid ah. Soosaarka baadiyaha tungsten carbide iyo ka baaraandegidda xoogga sare, waxay u adkeysan kartaa culeys dheeri ah, oo leh xasilooni kiimikaad sare leh, alkali, aalkolada, ether, hydrocarbons, acid, saliid, saabuunta, biyaha (biyaha badda), oo aan lahayn ur, aan sun ahayn, dhadhan lahayn, astaamo aan miridhku ahayn, oo si ballaaran loogu isticmaalo warshadaha batroolka ee bamka saliidda ee submerged, bamka biyaha.

Tilmaamaha Alaabta

1. Tungsten Carbide Bearing Bushings waxay leeyihiin jilayaasha iska caabbinta xirashada sare, iska caabinta daxalka sare iyo sifooyinka wanaagsan ee cadaadiska.

2. Waxaa si weyn loogu isticmaalaa warshadaha batroolka iyo warshadaha kale ee u yeera sifooyin sare oo kaynta ama shaft gacmaha.

3. Tungsten carbide BEARING waa sheyga aasaasiga ah ee ka mid ah walxaha isku dhaca. Waxaa si ballaaran loo isticmaalaa sida qaybaha aasaasiga ah ee xiritaanka. Iyo baadiyaha si weyn ayaa looga qaataa warshadaha petrochemical sababtoo ah waxqabadkeeda ugu fiican sida kartida xirashada, daxalka ka hortagga iwm.

Habka wax soo saarka

Wax-shiidid--Qayb-siinta sida loo baahan yahay--Shiidid Qoyan---qalalan--Granulation--Riix--Sinter--Inspection-- Xidhmada

Alaabooyinka la xidhiidha

Buushka Tungsten Carbide

Gacmaha Carbide ee bamka centrifugal

Hagaha Drill Tungsten

Gacmaha Shaft Carbide Axle

Carbide Plugs

Kubadaha Valve ee Carbide.

Kuraasta Valve ee Tungsten Carbide

Saliida Tungsten Carbide iyo Gaaska Dabiiciga ah ee Xiro Qaybaha iyo Qaybaha

Tungsten Carbide Nozzles

Qaybaha Pump Cadaadiska Sare ee Tungsten Carbide

Tungsten Carbide oo loogu talagalay -xakamaynta socodka

Qaybaha bambada centrifugal

Tiles-ka-xiran Carbide Centrifugal

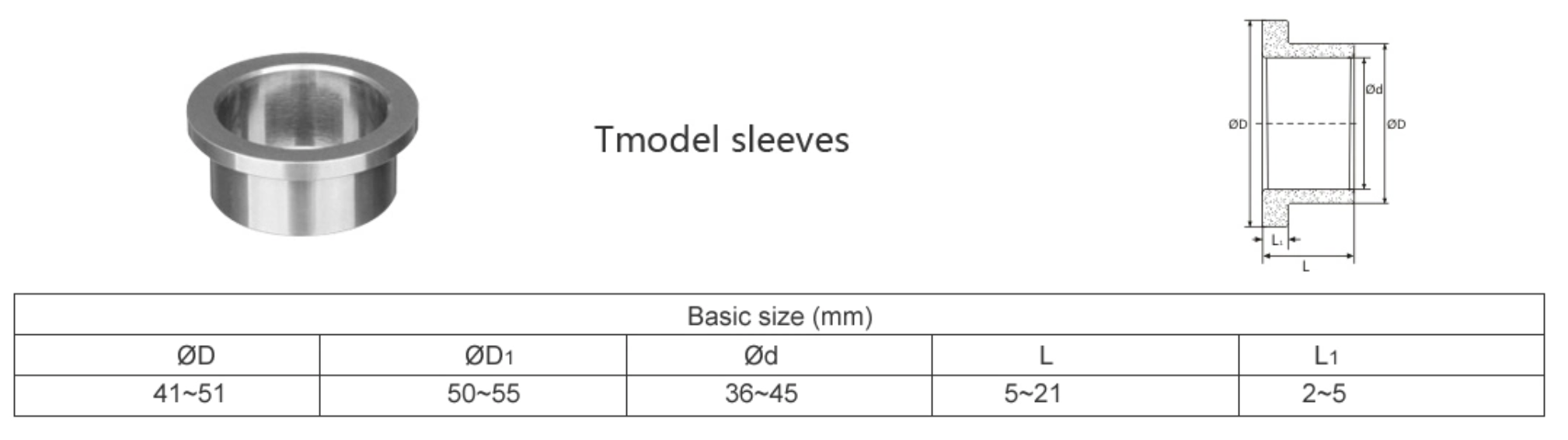

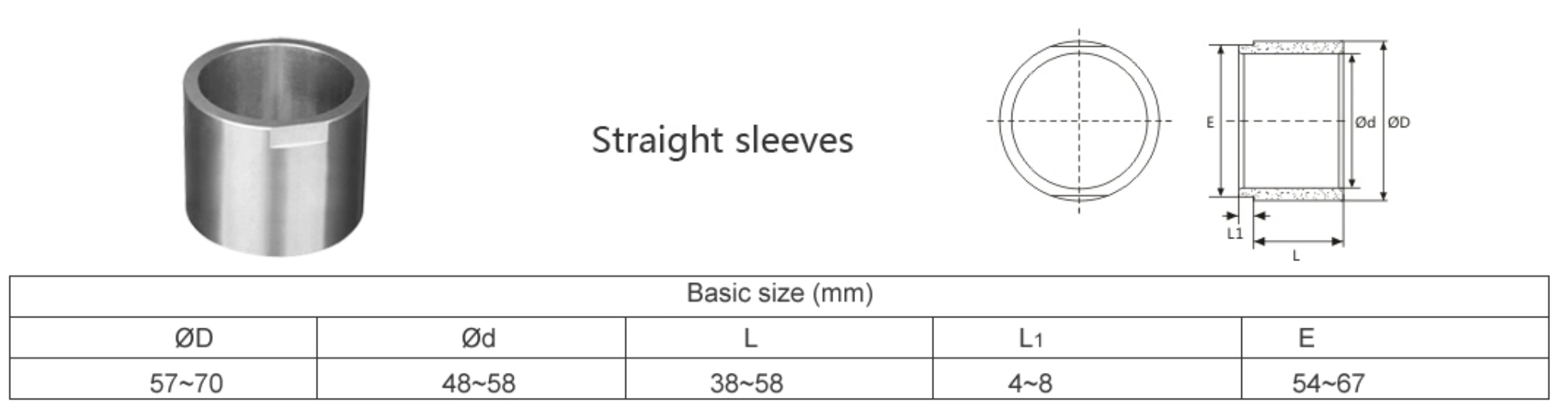

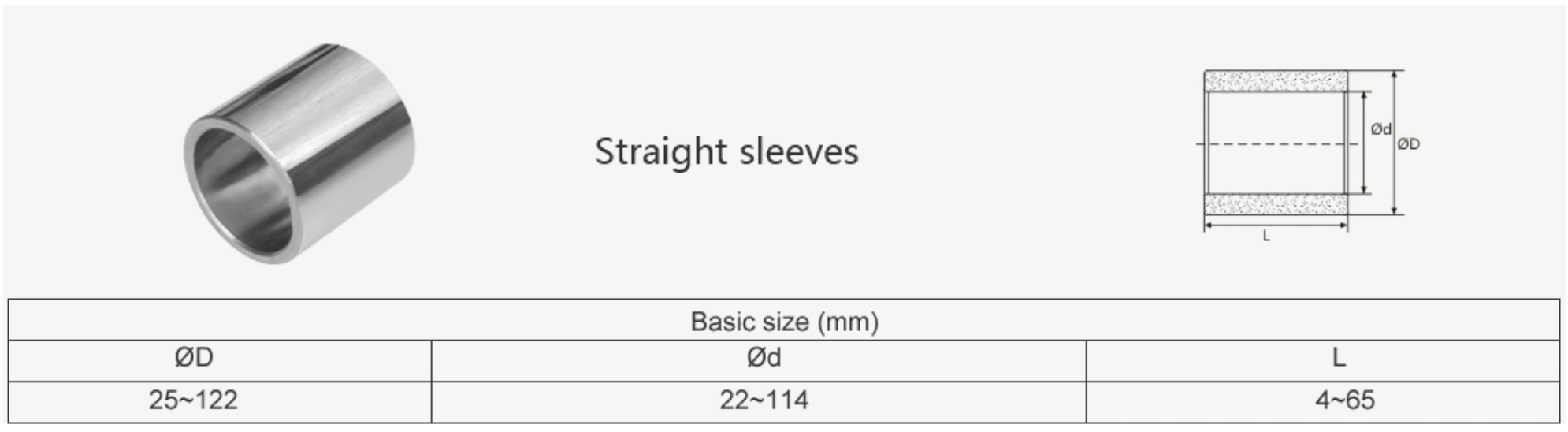

Jaantuska cabbirka alaabta

Miiska alaabta

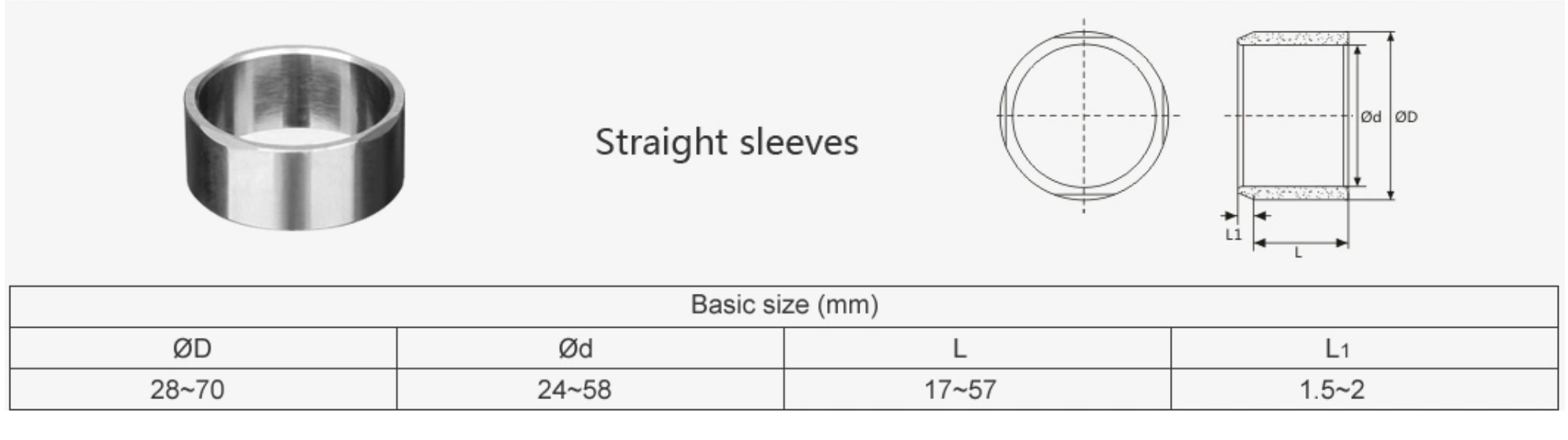

| Darajo | ISO | Tilmaamid | Codsiga carbide tungsten | ||

| Cufnaanta | TRS | Adag | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | U qalma mashiinada kabka la qaboojiyey, birta shubka daawaha ah, birta celisa iyo birta daawaha Sidoo kale u qalma mashiinada kabka caadiga ah. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | U qalma farsamaynta dhamaystirka iyo farsamaynta badh-dhamaadka ee birta kabka ah, birta aan birta ahayn, daawaha iyo alaabta aan daawaynta lahayn. Sidoo kale u qalma sawirista siliga birta iyo birta aan birta ahayn, laydhka korantada ee isticmaalka juqraafi iyo birta iwm. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | U qalma farsamaynta qallafsan ee birta kabka ah, birta aan birta ahayn, alaabta aan birta ahayn, sawirista birta, birta aan birta ahayn iyo tuubooyinka, laylisyada kala duwan ee isticmaalka juqraafiyeed, qalabka wax soo saarka mishiinka iyo xidhashada qaybaha. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | U qalma farsamaynta xawaarihiisa hoose, daawaynta titanium-ka-shiidka iyo daawaynta refractory, gaar ahaan qalabka la gooyey iyo jeexjeexa xariirta. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | U qalma samaynta laylisyada laylisyada culus ee dhagaxa: jajabyada la goyn karo ee loo isticmaalo qodista godka qoto dheer, trolleyga dhagaxa dhagaxa iwm. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | U qalma qodista dhagaxa adag, biraha birta ah ee leh saamiga cadaadiska sare, sawirida tuubada, qalabka feerka, golaha xudunta u ah biraha birta ah ee tooska ah iwm. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | U qalma samaynta dhimasha saamaynta hoose leh sida qaybaha saacadaha feedh, qolofka baytariga, koofiyadaha yaryar iwm. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | U qalma samaynta caaryada madaxa qabow, shaabada qabow iyo riixista qabow ee loo isticmaalo soo saarista qaybaha caadiga ah, biraha iwm. | |